La détection précoce des défauts de roulements est l’une des préoccupations majeures de l’industrie, mise en avant l’augmentation des vitesse de rotation des composants. De nombreuses méthodologies de post-traitement basées sur différents types de capteurs ont été proposées dans le passé, sans qu’aucune d’entre elles ne se distingue réellement de la méthode classique d’analyse de l’enveloppe d’un signal accélérométrique. Cet article présente une méthode de diagnostic originale qui, associée à l’analyse de la vitesse angulaire instantanée, apporte une nouvelle contribution au sujet.

IAS Diagnosis BeaFEM

Détection précoce des défauts de roulements

Auteur(e)s

R. Bertoni

Vibratec

28 chemin du Petit Bois, 69130 Ecully, France

H. Andre

Université de Lyon, Université Jean Monnet, LASPI EA3059,

42023 Saint-Etienne, France

20 Avenue de Paris, 42334 Roanne Cedex, France

ABSTRACT

Early detection of bearing faults is one of the major industrial concerns, brought to the forefront by miniaturization and the increase in component rotation speeds. Many post-processing methodologies based on different types of sensors have been proposed in the past, without any of them really distinguishing themselves from the classical method of squared envelope analysis on an accelerometric signal.

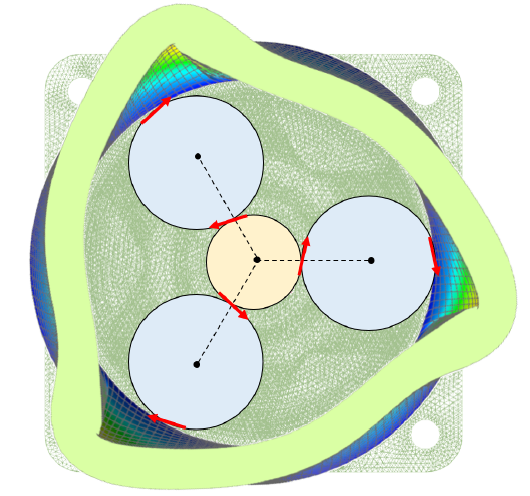

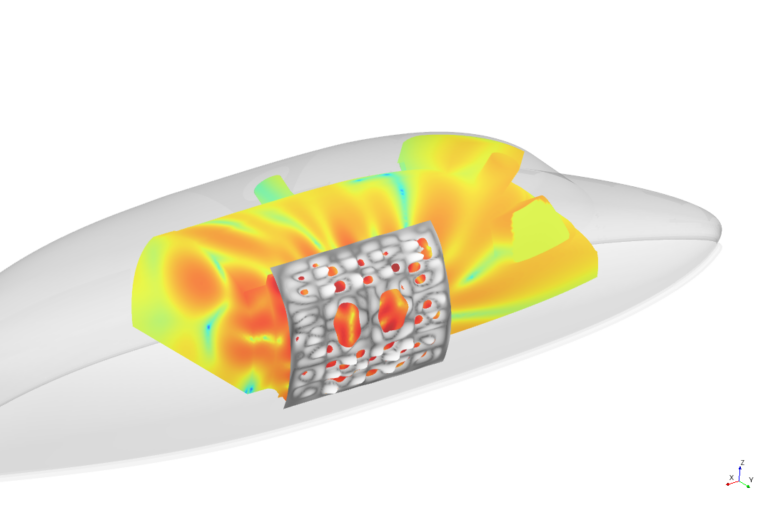

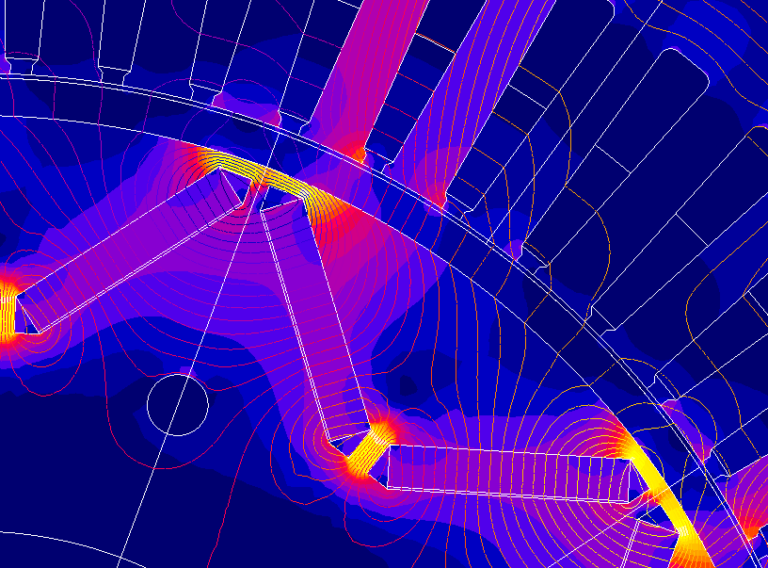

This paper presents an original diagnostic method which, associated with the analysis of the Instantaneous Angular Speed (IAS) signal, brings a new contribution to the subject. This method is based on the estimation of the characteristic frequency, optimized to detect and track a bearing fault. If the characteristic frequencies BPFO, BPFI and FTF are unknown a priori because they depend on poorly controlled parameters (such as the contact angle), they remain kinematically linked by the cage motion.

The results obtained on an industrial test bench show that it is possible to detect the generation of an inner ring defect with an incremental encoder In this paper, the BEAring Frequency Estimation Method (BeaFEM) is presented and tested on two application cases: an inner ring fault and a ball fault. The ball defect is particularly detailed because the detection of its characteristic frequency is more difficult. Indeed, when it leaves the loading zone, the ball undergoes a slip independent of the cage motion and the characteristic frequency of the ball defect (BSF) is slightly lower than the one obtained by optimizing the BPFO-BPFI-FTF characteristic frequencies via BeaFEM. This difficulty is circumvented by applying the envelope on the IAS signal.

IAS Diagnosis based on a BEAring Frequency estimation Method (BeaFEM)

Accédez à l’entièreté de la publication