Context & issues

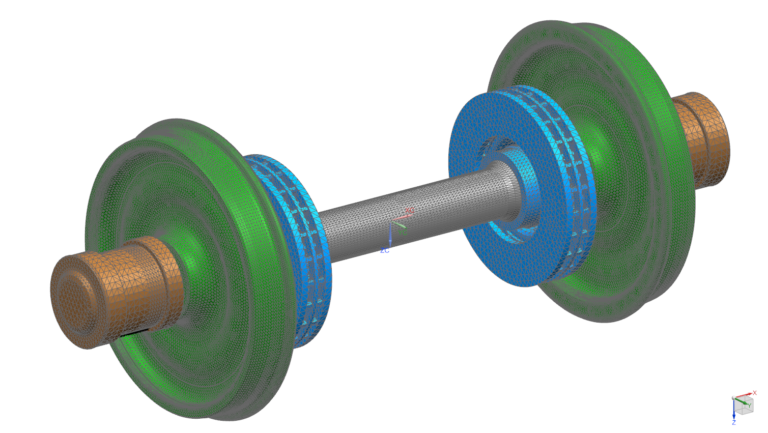

Industrial structures and components are subject to severe stresses: static forces, vibrations, fatigue, shocks, and even earthquakes. These stresses can cause early failure, premature wear, or costly production stoppages.

In this context, contracting authorities and certification bodies require compliance with international standards such as EN 12663, IEC 61373, Eurocode, and UIC. Products must therefore meet strict standards to ensure structural safety, reliability and durability.

Without reliable mechanical and computational validation, the risks are high: breakages, cracks, costly oversizing, or product recalls that can affect reputation and industrial performance. A rigorous approach, combining advanced calculations and possibly experimental testing, is essential to overcome these challenges.