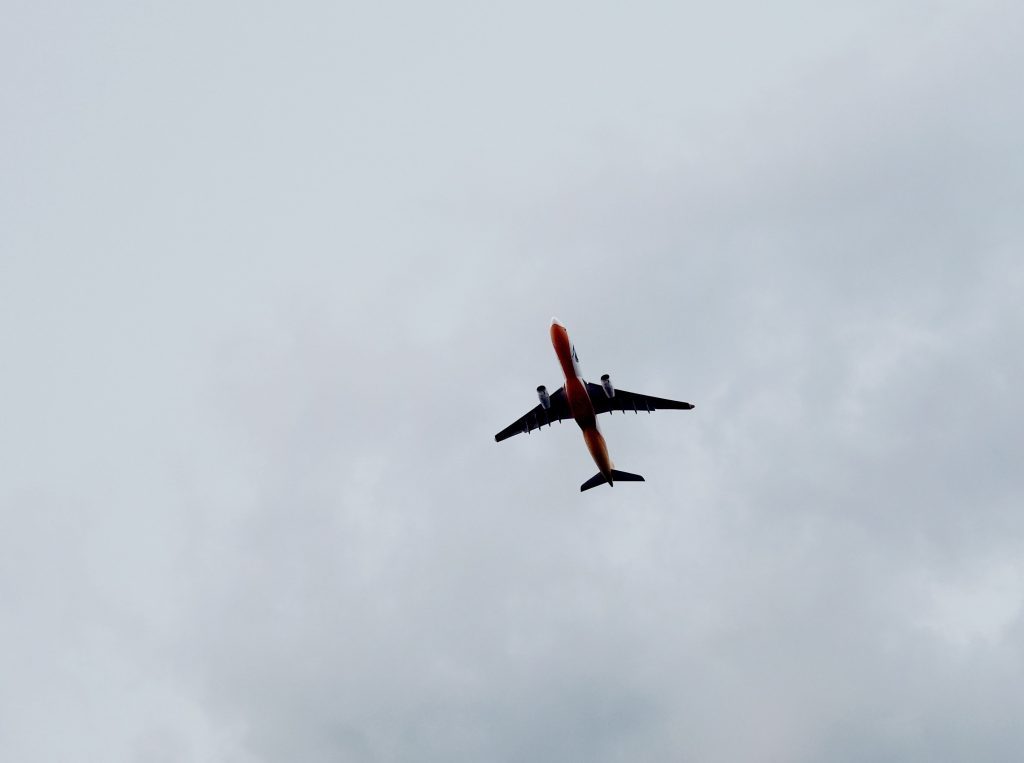

Developing the low-carbon aircraft of tomorrow is a key concern for all players in the aeronautics industry.

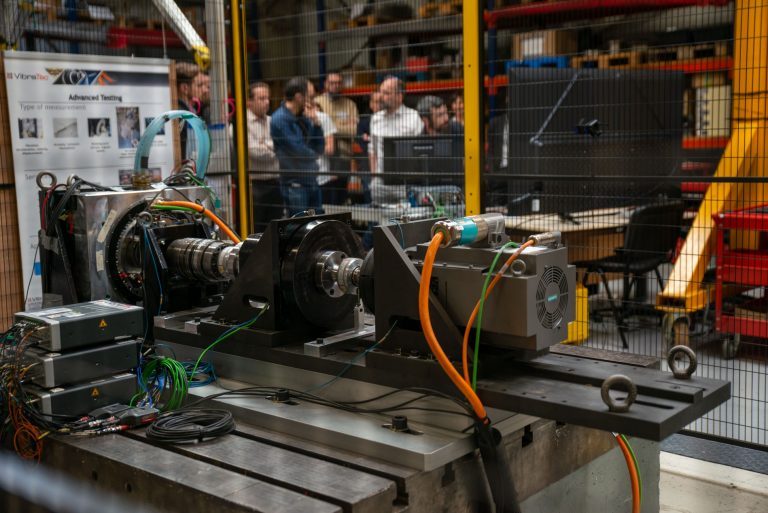

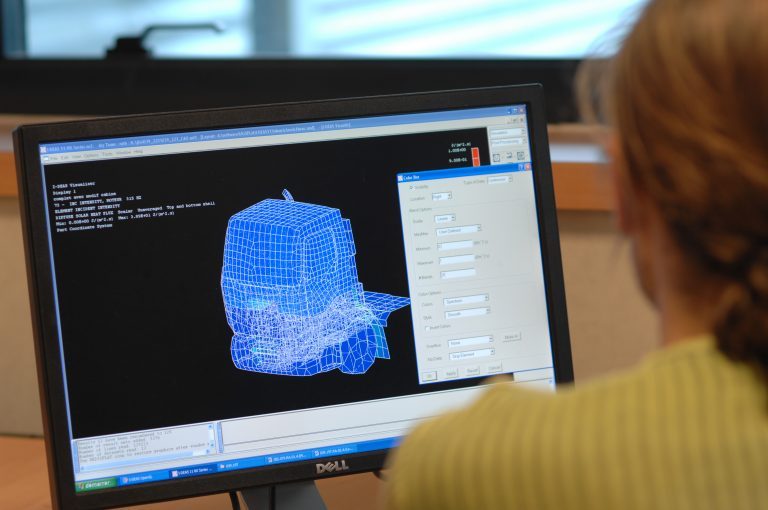

As part of the drive to reduce gas emissions from air traffic, the risks associated with the mechanical integration of new equipment in hybrid-electric propulsion systems are being addressed.

Electric hybridization of aircraft engines has been identified as a promising technology for reducing emissions, covering a wide range of aircraft.