The aim of our diagnostics is to identify the causes of breakdowns.

This is the first step; the final aim is to provide recommendations and find appropriate solutions. In agreement with your technical teams, we support you in finding, selecting and implementing the best compromise in line with your economic and technical constraints. Finally, we dimension the solutions and ensure on-site acceptance.

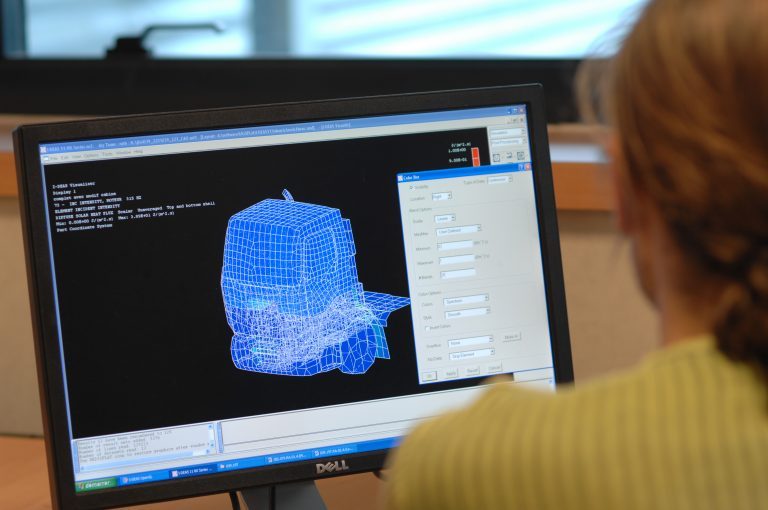

Vibratec applies a methodology that combines an experimental approach (on-site measurements) with a numerical approach (creation of a finite element model of the structure). Once the numerical model has been updated using the measurements, it is possible to assess the influence of modifications.

The main diagnostic techniques used are: