Implementation and validation of calculation and optimization methods for the design of electrical machines

The project’s work has demonstrated the benefits of coupling electromagnetic and mechanical model reduction techniques to reduce calculation times. In the case of the high-speed motor, calculation time was reduced by >60%. These methods offer significant potential for optimization studies, or for studies of dispersion due to manufacturing uncertainties, all of which require numerous computational iterations.

Arobust multi-criteria optimization technique has been introduced: this method makes it possible to reduce machine noise for several operating points and/or frequencies, while maintaining machine performance (torque, efficiency).

A calculation method has been developed to model and optimize the mechanical properties of resins used in the manufacture of certain electric motors for acoustic purposes.

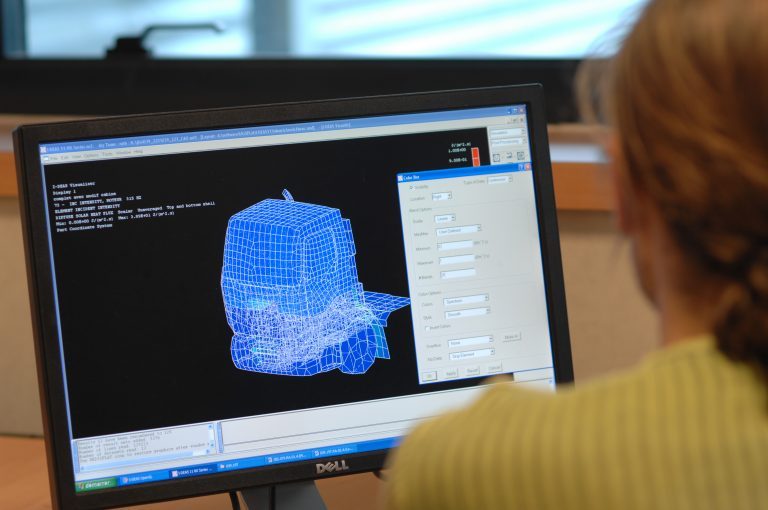

Finally, some of these methods have been integrated into two industrial software packages (Flux and FluxMotor), enabling designers to analyze the vibro-acoustic performance of machines while reducing the need for prototypes.

Bringing these methods to market represents a very promising step forward for the industry, with very wide-ranging applications:

- They can be applied at all stages of the design process: from pre-design studies where different design choices need to be quickly discriminated, to detailed design studies where geometries are finely optimized.

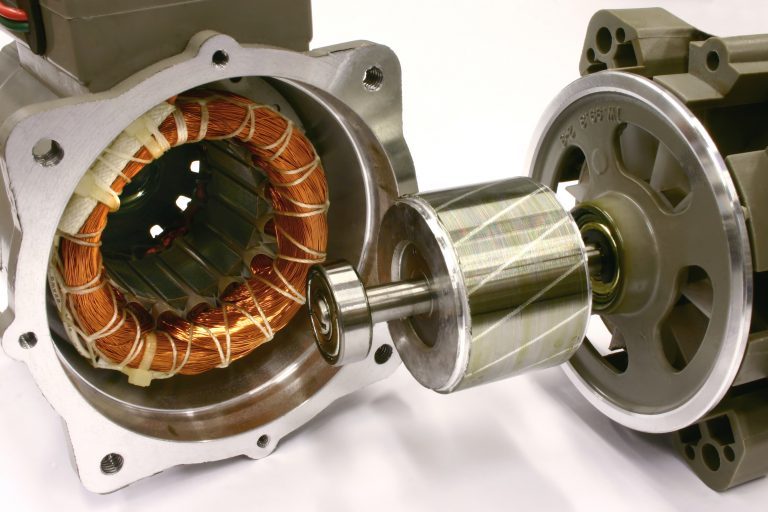

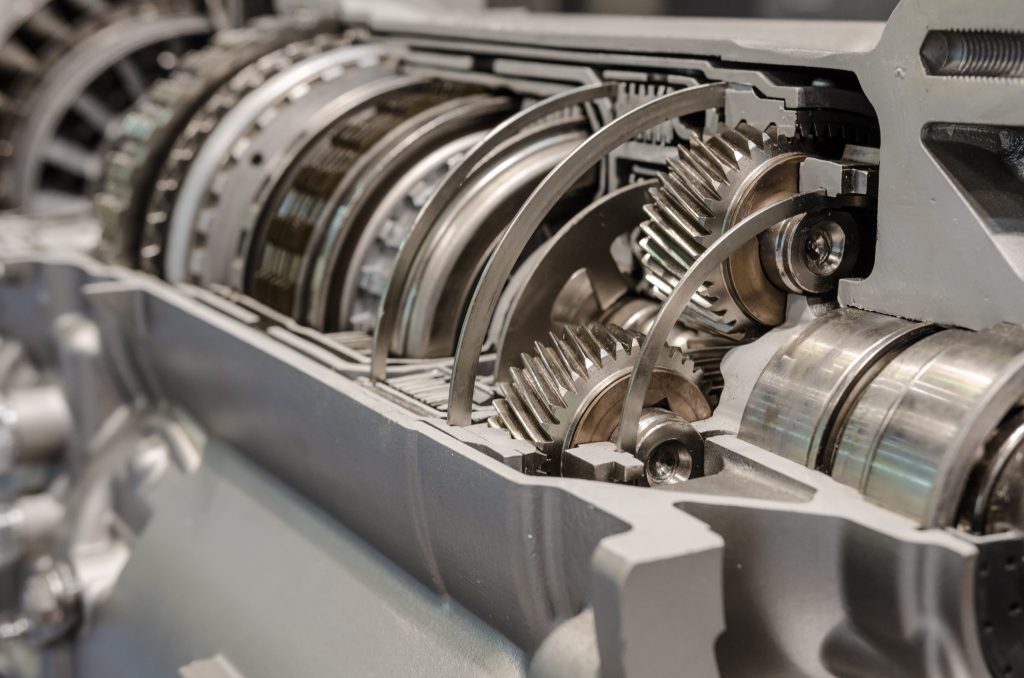

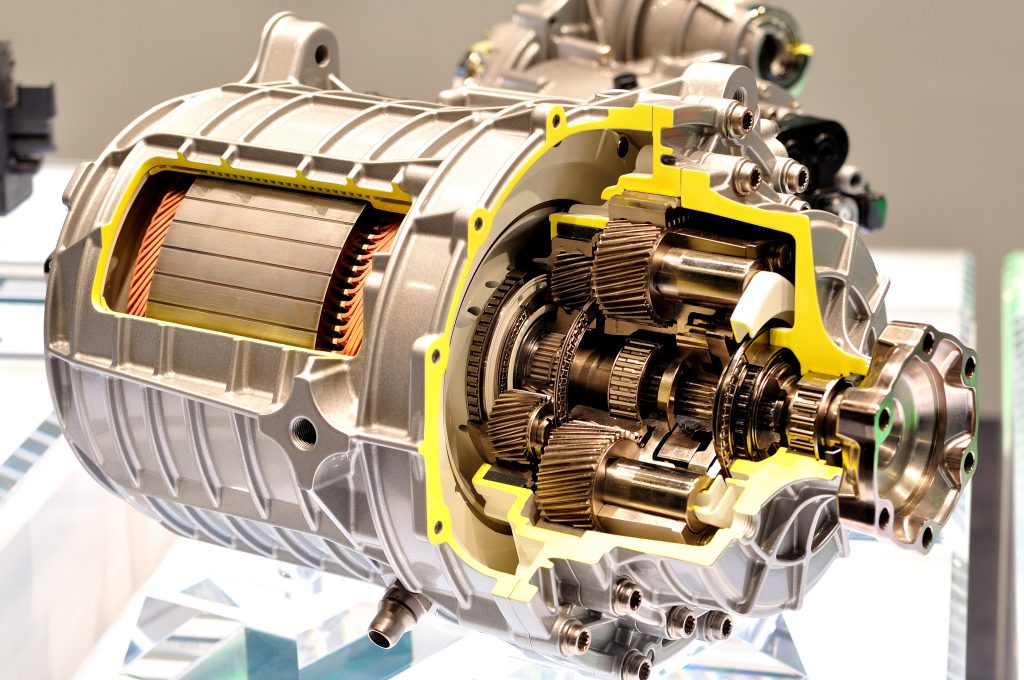

- They are potentially applicable to all types of electric machines (synchronous or asynchronous machines, variable reluctance machines, axial flux machines, etc.), for all industrial sectors.

Demonstrating the feasibility of technical solutions to reduce the noise radiated by electric motors

As part of a partnership with Von Roll, the benefits of optimizing an impregnating resin according to acoustic criteria were demonstrated through experimentation, with very significant gains (in the case of the high-speed machine from 30dB to 40dB), for the entire temperature operating range defined in the specifications.

We were also able to demonstrate the benefits of using stators with linked teeth to increase stator stiffness (gains of the order of 10dB to 20dB), thereby confirming our design choices.

Finally, an approach has been developed to correlate the geometric tolerances of motor stator construction (by X-ray tomography characterization) with radiated noise levels.

Economic impact

The e-Silence project has also enabled all the industrial partners to maintain and create permanent jobs beyond the duration of the project, through increased sales.

- Between 25% and 30% of MMT sales in 2021 and 2022 came from work related to the design of quieter engines, thus exploiting the work of the e-Silence project.

- The project will enable Vibratec to maintain its competitive edge. During the life of the project, sales around this theme increased by 50% (representing 4 FTEs). An equivalent increase is expected over the next three years (increase in the number of electrification projects in the automotive and aeronautics industries).

- Altair has been able to raise the competitive level of its software in relation to its competitors, and thus has major assets to gain market shares: the new functionalities introduced in Flux and FluxMotor are already being used by several customers, both in France and internationally. The number of customers (mainly in the automotive sector) using Flux and FluxMotor has increased by 20% and 50% respectively, between 2020 and 2022. Annual growth of between 20% and 30% is expected over the next five years, given the prospects for growth in the electrification of means of transport.