Vibration analysis makes it possible to assess the health of a machine and propose maintenance measures.

Vibration levels are measured at several points on a structure, machine or piece of equipment.

These data can be used for comparison with admissible values according to current standards or project/client specifications. Measurement results are also a key element in any diagnosis of non-conformity, breakdown, reliability or residual life study. There are several types of vibration analysis, depending on the context and purpose. The two main types are operating and stationary analysis.

Data obtained from vibration analysis during operation can be compared with admissible values derived from current standards, for example, during equipment acceptance tests.

These measurements are essential for detecting, understanding and analyzing the origin of faults or anomalies in order to optimize product reliability, as they would indicate the degradation of a component that could be subject to special maintenance or monitoring (e.g. bearing failure, rotating shaft misalignment, pulsation phenomenon, etc.).

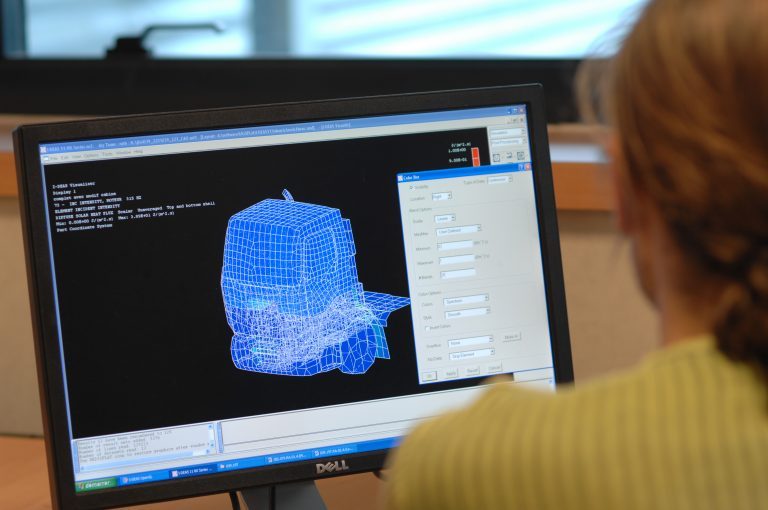

The aim of stationary vibration analysis, or Experimental Modal Analysis (EMA), is to obtain the eigenmodes of a structure, machine or piece of equipment, each characterized by a frequency, damping and deformation.

Knowledge of a product’s eigenresponse is essential during a complete diagnosis. AME is necessary as a complement to operating vibration analysis, as comparison of the results of the two types of measurement makes it possible to determine whether the vibration phenomenon observed is of structural origin (e.g. appropriation of a structural mode) or whether it stems from an internal fault in the machine (e.g. an unbalance fault).