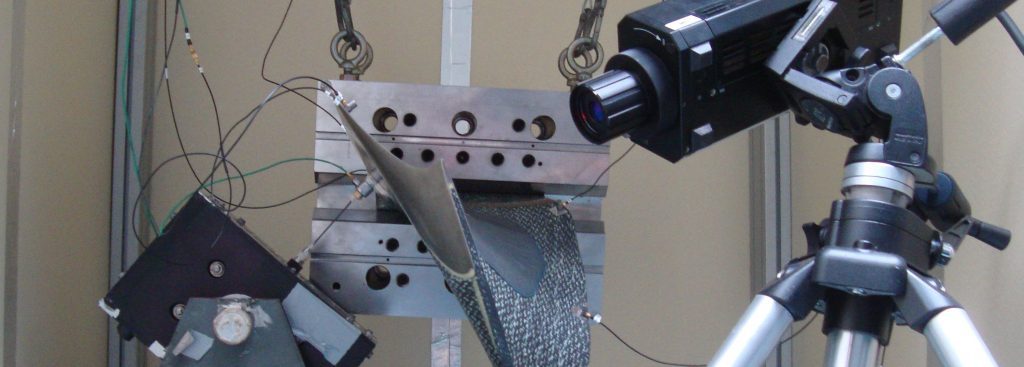

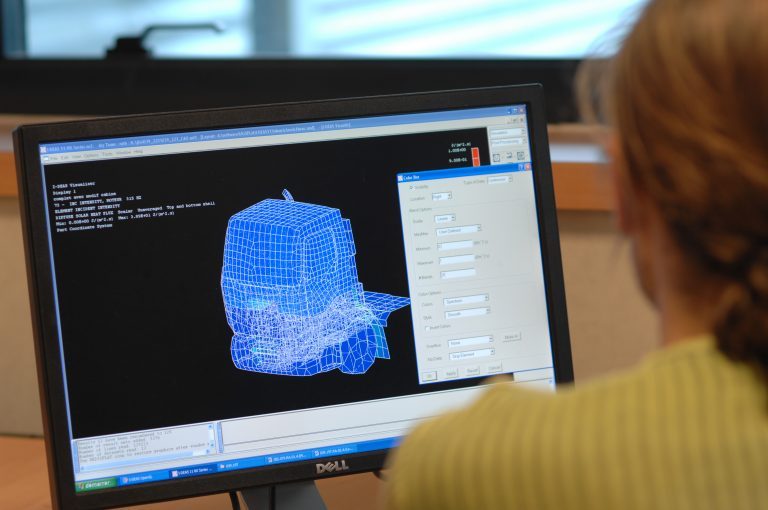

At Vibratec, we are proud to put our expertise, equipment and experience at your disposal to solve your measurement problems on rotating elements such as shafts, crankshafts, transmission elements, alternators, etc. We are confident that our skills and state-of-the-art equipment will enable us to meet your needs for acyclism and instantaneous speed measurements.

We offer a full range of measurement services to meet your needs, from planning and carrying out tests to delivering detailed reports. Our team of experts is highly qualified to perform acyclism and instantaneous velocity measurements using a variety of measurement methods and techniques.