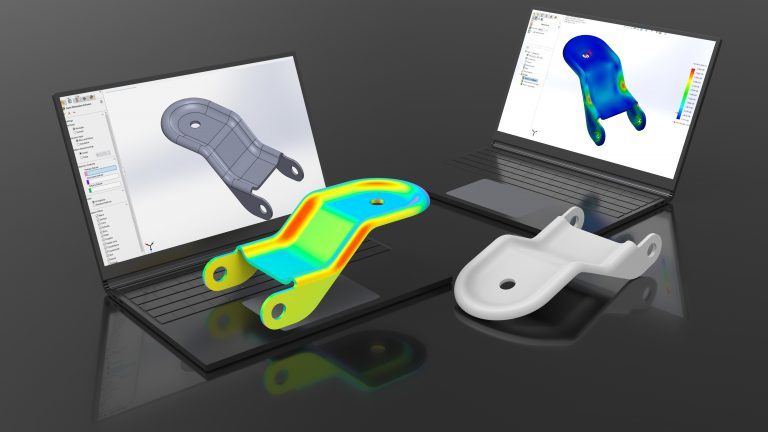

Whereas product qualification requires the production of prototypes, and therefore advanced product design with high testing costs, simulation enables numerous tests to be carried out through the development of virtual prototypes.

Finite element modeling covers a wide range of analyses, including solid dynamics, kinematics and acoustics. By recalibrating models with experimental data, we can ensure the fidelity of digital models, making it possible to carry out numerical tests incorporating realistic excitations.