Measurement location definition

Measurement locations must be carefully chosen to enable accurate vibration monitoring and to detect potential mechanical problems. Common locations for vibration measurements on a water turbine include:

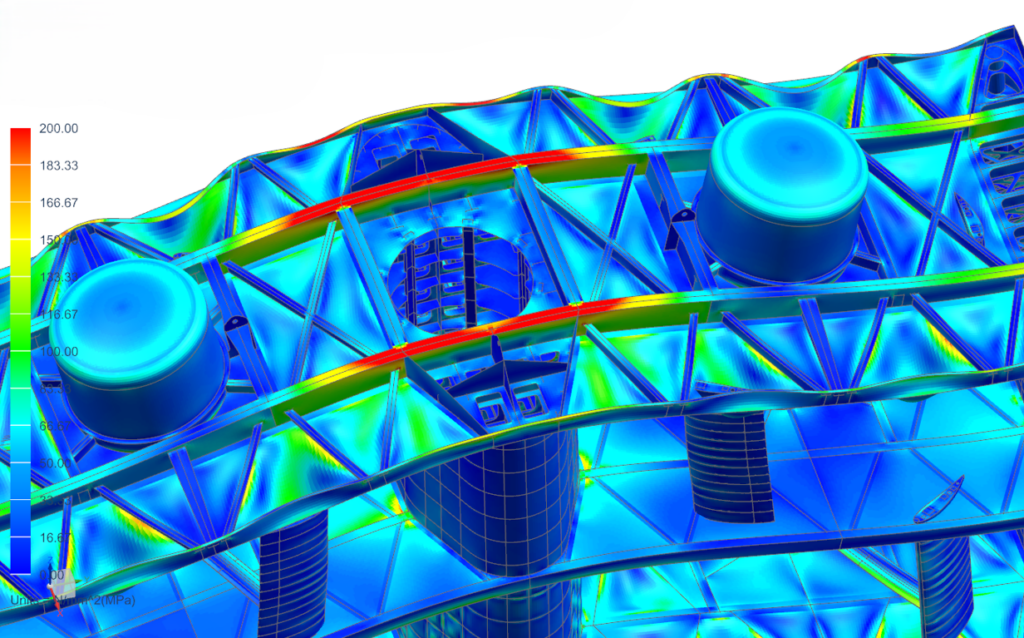

- Bearings: Bearings are contact points where the water turbine’s shafts and propellers are supported. Vibrations at these points can indicate mechanical problems such as bearing damage or imbalances in the water turbine.

- Gears: Gears transmit power to the water turbine, and can be a source of excessive vibration if damage or mechanical problems occur.

- Nacelle: The nacelle is the part of the water turbine that contains the electrical and electronic components. Vibrations here may indicate problems with electronic or electrical components.

- Tower: The tower is the structure that supports the water turbine. Vibrations here may indicate structural problems with the tower or foundation.

It’s important to note that the choice of measurement locations will depend on the specifics of each water turbine.

Hardware definition (sensors, analyzer, data storage, data transmission)

The equipment used for vibration monitoring of tidal turbines comprises several key components:

- Sensors: Vibration sensors are devices that measure mechanical vibrations on the water turbine. They can be of various types, such as accelerometers, speed sensors or pressure transducers. Sensors can be installed at appropriate locations on the wind turbine to measure vibrations at critical points.

- Analyzers: Vibration analyzers are devices for processing the vibration data collected by the sensors. Vibration analyzers can be portable or fixed, and can be equipped with analysis software to interpret vibration data and detect potential problems. They can also be used to determine vibration frequencies, amplitudes and modes.

- Data storage devices: Vibration data collected by sensors must be stored for later analysis. Data storage devices can be internal or external hard disks, memory cards or cloud storage devices.

- Data transmission systems: Vibration data can be transmitted remotely for further analysis or real-time monitoring. Data transmission systems can include wired or wireless connections, cellular modems or satellite communication systems.

Supplier consultation and selection

Selecting a supplier for water turbine vibration monitoring equipment is an important step in ensuring that the equipment meets the specific requirements of the project, and guarantees reliable and accurate vibration monitoring.

- Define project specifications: It is important to define project specifications in terms of monitoring capabilities, sensor types, analyzers, storage capacities and data transmission systems. These specifications will help identify suppliers who can meet the project’s needs.

- Search for suppliers: It is advisable to search for several suppliers to obtain a range of solutions and prices. Suppliers can be found online, in company directories or through recommendations from industry professionals.

- Compare offers: Once suppliers have been identified, it’s important to compare their offers in terms of cost, quality, service and guarantees. Offers should also be compared against project specifications to ensure that they meet specific needs.

- Ask for references: It is advisable to ask for references from previous customers/clients to assess the quality of suppliers’ products and services.

- Verify compatibility with existing systems: It’s important to confirm that the supplier’s proposed hardware is compatible with existing systems, such as water turbine monitoring systems, to ensure trouble-free integration.

- Evaluate after-sales service: It’s important to consider the quality of after-sales service offered by suppliers, such as maintenance, repair and equipment replacement options.

On-site installation

The installation of water turbine vibration monitoring equipment is an important step in ensuring that the equipment operates correctly and provides accurate and reliable data. Here are some key steps for on-site installation:

- Plan the installation: Before starting the installation, it is important to plan the location of the sensors, analyzer and data storage device to ensure optimal vibration monitoring. It is also important to ensure that the sensors are installed in such a way as to avoid electromagnetic and mechanical interference.

- Installing sensors: Vibration sensors should be installed on those parts of the water turbine that exhibit significant vibration. Sensors must be securely mounted using appropriate brackets and fixings to ensure accurate and reliable vibration measurement.

- Installing the analyzer: The vibration analyzer must be installed in a safe, dry place, protected from vibration and electromagnetic interference. It should be installed in an electrical cabinet to protect against weather damage and to facilitate access to the equipment for maintenance and troubleshooting.

- Installing the data storage device: The data storage device should be installed close to the analyzer to enable fast and easy data transmission. It should be installed in an electrical cabinet to protect against weather damage and to facilitate access to the equipment for maintenance and troubleshooting.

- Perform tests: After installation, it is important to confirm that all equipment components are working properly and are capable of collecting accurate and reliable vibration data. Vibration tests can be carried out to verify the accuracy of the data collected.

- Ensuring safety: Installation of vibration monitoring equipment must be carried out by qualified professionals to ensure operator safety and to avoid the risk of damage to the equipment. Safety measures, such as de-energizing the equipment during installation and careful handling of sensors, must be taken to minimize the risk of accidents.