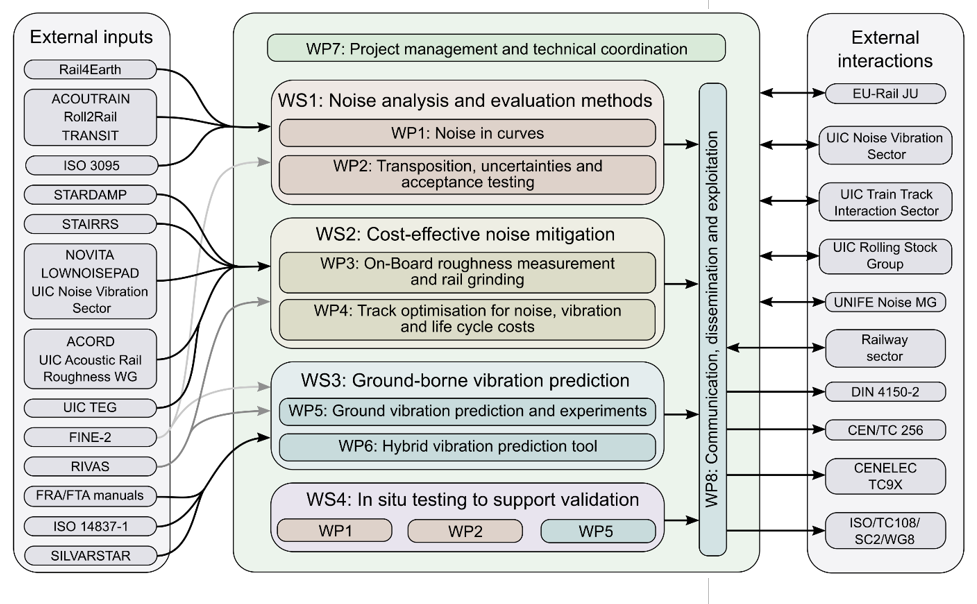

Experimentally validated methods for predicting noise and ground vibrations

Curve noise is increasingly mentioned in the technical specifications for new rolling stock, with the ‘right’ to produce noise limited to a few dB compared with straight-line traffic. Depending on the geometry of the curve, different types of noise can be generated: rolling noise, wheel flange/rail friction noise, squeal noise on small radius curves. Models will be developed and validated for each of these noises.

The transposition of pass-by noise is a recurring problem during acoustic acceptance tests for new rolling stock, where the track on which the vehicle will be operated is not necessarily the same as that used for the acceptance tests. Transposition methods have been proposed and partially evaluated in previous projects (ACOUTRAIN and TRANSIT). QuieterRail will extend the scope of validation of these methods by considering frequent traffic configurations in urban areas (laying of flexible track, laying of track on a slab).

Technical recommendations for on-board systems for reading the acoustic quality of tracks

An effective way of reducing rail rolling noise is to monitor the acoustic roughness of the track using on-board measurement systems and then to perform acoustic rail grinding if necessary. A comparative analysis of on-board measurement systems used to monitor rail roughness by infrastructure managers and grinding service providers will be carried out. The aim will be to establish a harmonised procedure for determining rail roughness levels from on-board sensor data.

Software for simultaneous noise, vibration and life cycle cost optimisation

Noise and/or vibration reduction solutions will be quantified in terms of life cycle costs (installation costs, maintenance costs, etc.), incorporating a financial value associated with environmental and health impacts. An open-source web tool will be developed to optimise the entire system by simultaneously considering noise, ground vibrations and life-cycle costs on railway tracks.

A software package for simultaneously studying the environmental impact of noise and vibration on a large scale using a single software platform

The collaboration with Wölfel, ISVR, KU Leuven and Vibratec will result in a unique software platform that will enable engineers to carry out noise and vibration environmental impact studies in a single software environment. The proposed hybrid calculation/measurement modular approach and the databases integrated into the software (rolling stock, track, ground and building) offer total modelling flexibility at every stage of the design process. The capabilities of the software developed in will be extended to take account of curves and impact excitations (e.g. crossing switches and crossings). The databases associated with the software, in particular the building transfer functions, will be expanded.