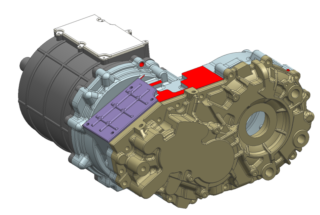

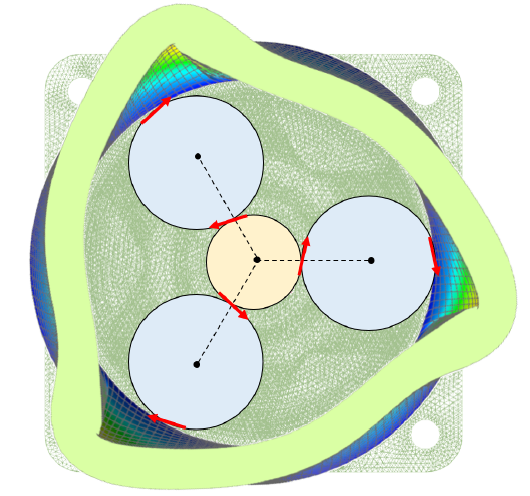

Designing an electrical machine is a complex process that involves many physics, objectives and constraints. Mechanical, thermal and energy performances are usually evaluated and optimized. In order to reach good NVH performance, the acoustic behavior of electrical powertrain has to be considered during the early design phase. Two excitations phenomena are to be considered: electromagnetic excitation within the airgap of the electric motor and meshing processes within the gearbox. The emitted noise is characterized by the emergence of high frequency pure tones that can be annoying and badly perceived by drivers.

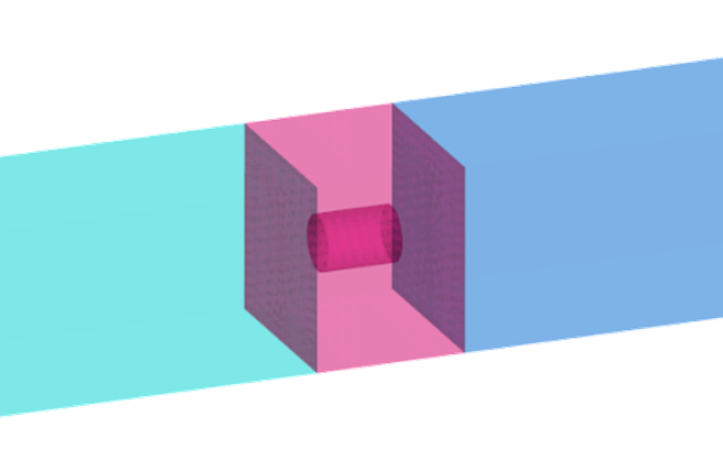

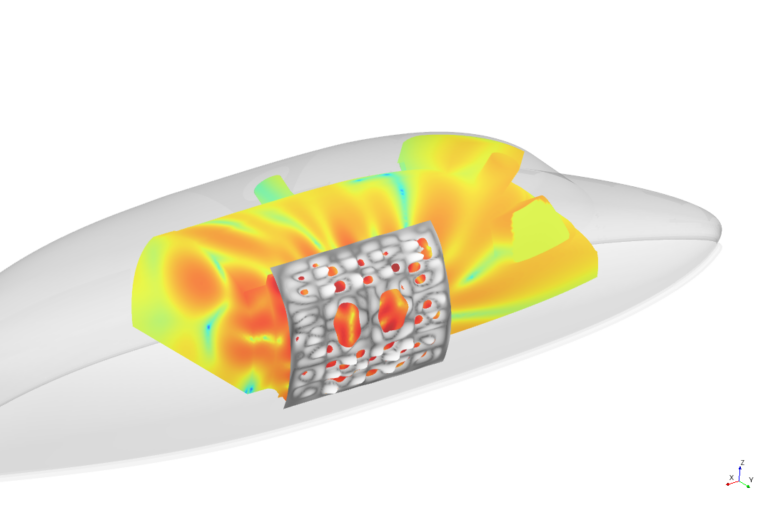

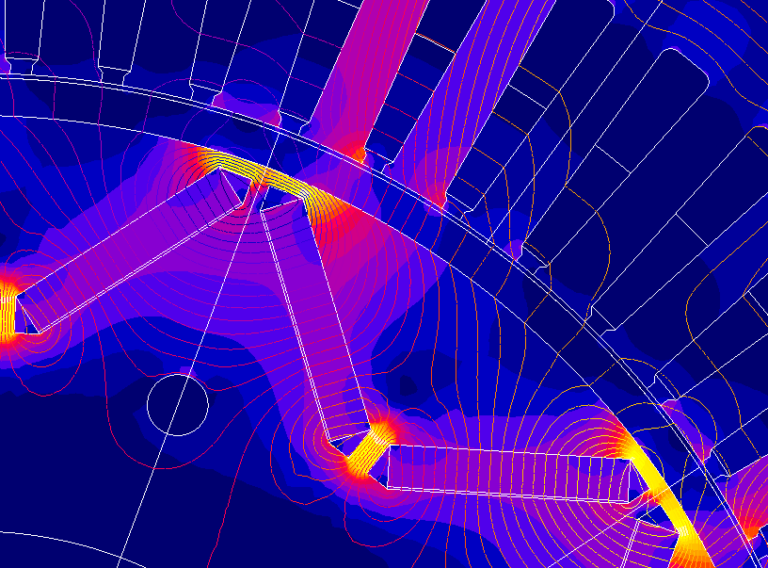

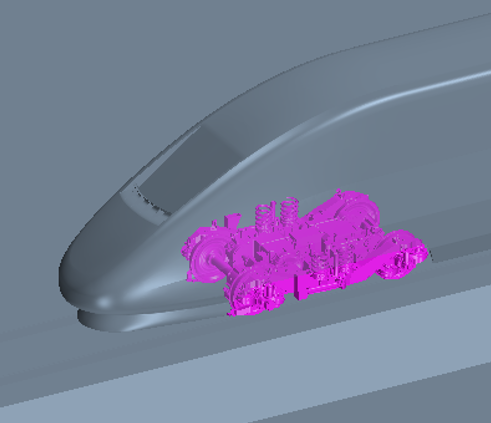

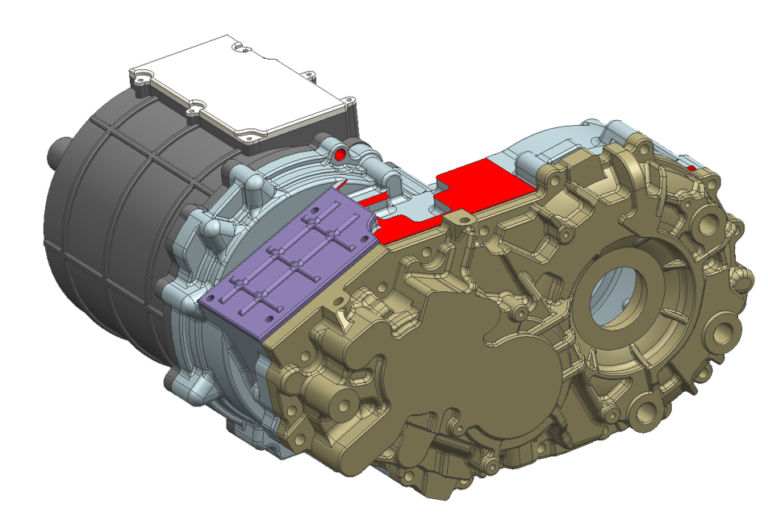

For these two sources, the paper will first briefly present efficient computation methods which can be used to estimate noise and vibration levels. For the electromagnetic excitation it relies on a numerical workflow which couples models belonging to the fields of electromagnetics for the Maxwell pressure computations, structural dynamics for the vibration response and acoustics for radiation estimation. For the gearbox excitation, it relies on the computations of excitations terms (Static Transmission Error and mesh stiffness fluctuation) and the spectral iterative solver to obtain the vibration response of the gearbox. Complete powertrain noise computations and examples of validations cases on industrial applications will be shown.

In a second step, the paper will focus on robust optimization methods able to take into account several optimization objectives (sound power, vibration, torque ripple, operating conditions, etc.) and constraints (global efficiency, maximum torque, etc.). In addition to classical deterministic optimization method, robust optimization methods aim at considering the effect of manufacturing tolerances, material properties dispersion and control uncertainties on the vibratory and acoustic levels to minimize, so that noise reduction are really obtained when the machine is manufactured and operated. The interest of robust methods will be illustrated on industrial applications, for electric motor topology optimization as well as gearbox teeth microgeometry optimization.