IDEFISC

IDEntification of FISsures in Composites

Context & Issues

In the global context of system and structure monitoring, early identification of defects is an important issue for all manufacturers, both for predictive maintenance and operational safety, and to control manufacturing processes or finished product quality.

In particular, non-destructive testing (NDT) methods for identifying defects in materials represent a major challenge in many industries (composite, plastics, foundry, civil engineering, etc.).

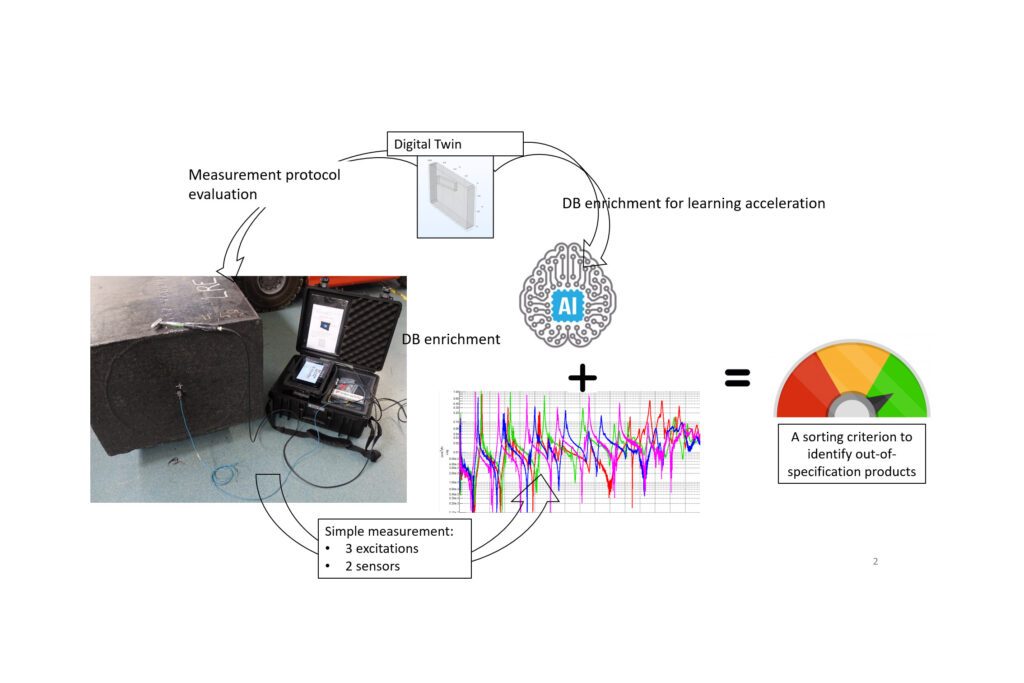

Within IDEFISC, an innovative scientific approach to medium-frequency waves (supported by the LTDS and artificial intelligence) provides detection efficiency superior to traditional NDT methods.

The effectiveness of the method has been demonstrated on a wide range of products, thanks to the provision of batches of parts by the manufacturers involved in the project (TOKAI CARBON SAVOIE, CLAYENS NP, SAFRAN COMPOSITES & SMAC).

The results have potential applications in the NDT and monitoring markets for systems and structures.

Challenges

01

Identify early warning signs of defects

02

Develop a tool for identifying defects in composite parts

03

Developing a tool for operational monitoring (SHM)

The IDEFISC project has enabled us to make a number of technical advances, synthesized into a demonstrator that can be used on industrial sites.

We were able to better define the use of AI methods and the place of digital technology in our non-destructive testing (NDT) offer based on acoustics and vibration, enabling us to better position and define our offers.

We had to integrate external routines and executables in our acquisition software to create measurement products integrating AI methods supplied in executable form and developed in-house or by third parties. We were also able to improve the adaptability of our vibration measurement product to integrate new protocols and more sensors.

Key Development Points

01

Control damping-related disturbances using a multi-frequency band approach

02

Detect defects on all scales using a combination of spectral approaches

03

Decision support for operational implementation based on AI and machine learning

Results

The IDEFISC project contributed to a number of technical advances, which have been synthesized into a demonstrator that can be used on industrial sites.

We have been able to better define the use of AI methods and the place of digital technology in our non-destructive testing (NDT) offer based on acoustics and vibration, enabling us to better position and define our offers.

We had to manage the integration of external routines and executables into our acquisition software to make measurement products integrating AI methods supplied in executable form and developed in-house or by third parties. We have also been able to improve the adaptability of our vibration measurement product to integrate new protocols and more sensors.

Contact

Hugo SIWIAK

Project Manager, Test Team Manager

Aurélien CLOIX

Test Engineer, Systems & test Benches

Project Specifics

1 M€

financing

2

specific software programs developed

3

years of development

Funding

This project benefits from “R&D Booster” support sponsored by