When designing equipment, it’s important to take into account the high dynamic loads to which it will be subjected. These loads can be determined by physical parameters such as accelerations, velocities, forces, moments and so on. For an efficient and resilient design, it is necessary to map these stresses throughout the life cycle of your products.

Our stress mapping service takes into account various factors such as transport (road, rail, sea, air), operating conditions, shocks and risk events, as well as the product’s environment. This analysis enables us to determine the most severe stresses your equipment will have to withstand, and to use them as a basis for designing more resistant, reliable and durable products.

The severe excitation program is another important tool for designing robust equipment. Severe excitation levels can be defined by physical quantities such as Spectral Power Densities (SPD) or Shock Response Spectra (SRS). These parameters characterize dynamic excitations at specific frequencies and are used to specify the stress levels to be taken into account in the design.

By taking these stresses into account, you can design stronger, more reliable and longer-lasting products, which can also help improve customer satisfaction and reduce maintenance and replacement costs.

Our severe excitation program uses these physical parameters to define the excitation levels to be applied to your equipment during testing. This allows us to simulate real-life operating conditions and verify the strength and reliability of your product. Excitation levels can be modified according to test results to adjust design and improve equipment performance.

To validate your product’s mechanical strength and strengthen its design, it is also important to clearly define its mechanical requirements in terms of strength, stiffness, durability and tolerances. We perform a load analysis to understand the forces that are applied to your system and how it responds to them.

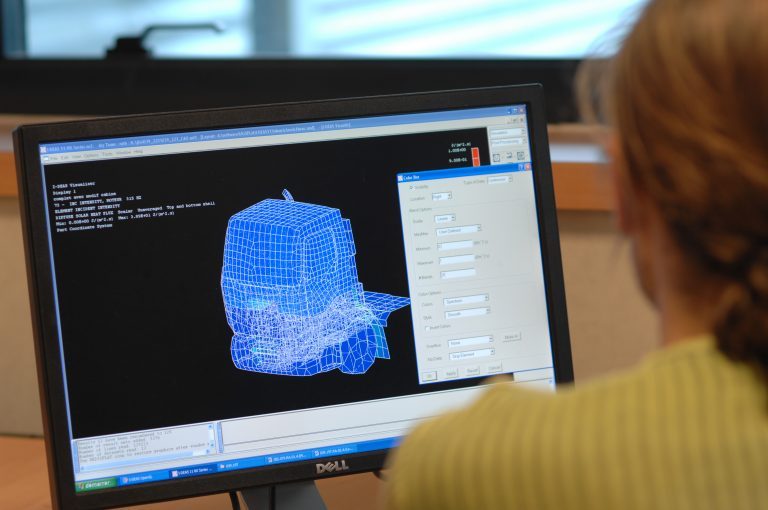

With our modeling and simulation software, we can create numerical models and evaluate the mechanical performance of your design. This allows us to see how it will behave in real-life situations, and use these results to improve the design.

Finally, prototyping your product validates the simulation results. Use high-quality materials and reliable manufacturing processes to reinforce the robustness of your product. And all this while complying with current safety standards and regulations.

By choosing our stress mapping service, our severe excitation program and our mechanical design expertise, you can improve the reliability of your product.